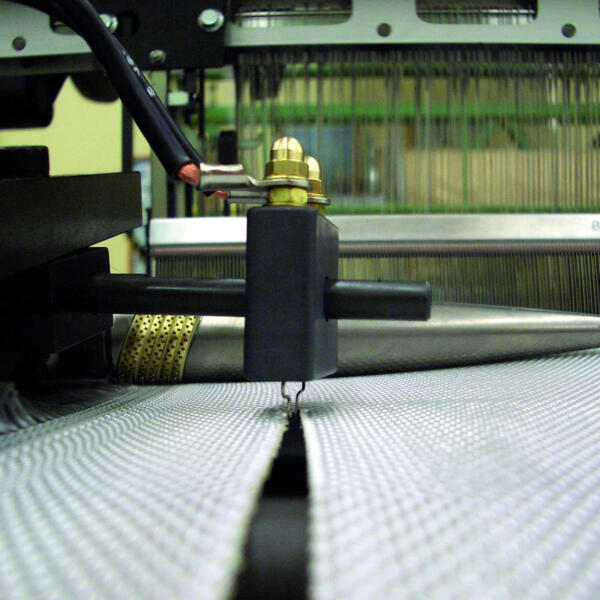

Fabric separation

WeftMaster® CUT-iT is the ideal fabric cutter system for thermal cutting from thin and light to dense and heavy synthetic fabrics. It increases the quality of the cutting and reduces style change times.

- All over the world, producers of high-end and technical fabrics take no risk and specify CUT-iT to guarantee a top quality and uniform selvedge. Making use of CUT-iT during the fabric production process ensures a quick return on investment for safety-critical products like airbags, tarpaulins or sailcloth.

- This recently developed product is highly demanded in cleantech, medtech, geotextiles, automotive and many more high-tech areas.

- A top quality and uniform selvedge is highly valued especially if the yield in post processing is dependent on it.

- The CUT-iT control unit offers precisely controllable settings and saves them as a style for later use. This makes style and article changes fast and easy.

- A single control unit handles multiple cutters, allowing separating fabrics into multiple webs.

Client-server mode opens wide range application on tape weaving machines

The WeftMaster CUT-iT control unit can operate in Client-Server mode with a maximum of 32 client units. When changing the setting on the server unit, the settings on all client units change simultaneously. This new functionality allows operating over 100 cutters in parallel.

Application examples

Discover instances where CUT-iT significantly contributes to a zero-defect manufacturing process for technical textiles. As this thermal fabric cutter system is suitable for thin and light to dense and heavy synthetic fabrics.

Airbag fabrics

WeftMaster CUT-iT for airbag fabrics. In case of the unexpected while driving a car, people are relying on airbags for their life protection. Hence, airbag fabrics must have flawless quality. Renowned weavers of airbag fabrics take no risk; they rely on Loepfe's CUT-iT to ensure their top quality fabrics have a perfectly defined and uniform selvedge.

Making use of the unrivalled features of CUT-iT during the fabric production process ensures a quick return on investment for safety-critical products such as airbags. The applications where CUT-iT improves a product’s quality are not limited to this showcase. All over the world, producers of high-end technical fabrics specify CUT-iT of Loepfe to guarantee a fabric selvedge without compromise. A top quality and uniform selvedge is highly valued when the yield in post processing is dependent on it.

Coated fabrics such as tarpaulins or sailcloth can only be perfect if the base material used has top aspect selvedge guaranteed by CUT-iT.

CUT-iT offers precise controllable settings for Loepfe´s hot wire cutters. The unit memorizes settings for later use. The client-server mode is very useful on tape weaving machines. CUT-iT has no analog controls like other controllers and hence has a better resistance to tampering. This recently developed product is highly demanded in cleantech, medtech, geotextiles, automotive and many more high-tech areas.

Sailcloth

Wind, water, salt and the highest loads. Sailing is something for true professionals and experts. Likewise making sailcloth, one of the most demanding high-performance fabrics, is produced only by specialized weavers.

A sailcloth must retain its shape even in high winds, but also allow and withstand strong stretching and this over a long period of time. In addition, the fabrics are constantly in contact with water and salt, which additionally stresses their surfaces. A fabric can only sustain these high demands if it has been manufactured to the highest quality.

Submit your data and you will be contacted by one of our experts