Yarn Monitoring System for Sectional Warping Machines

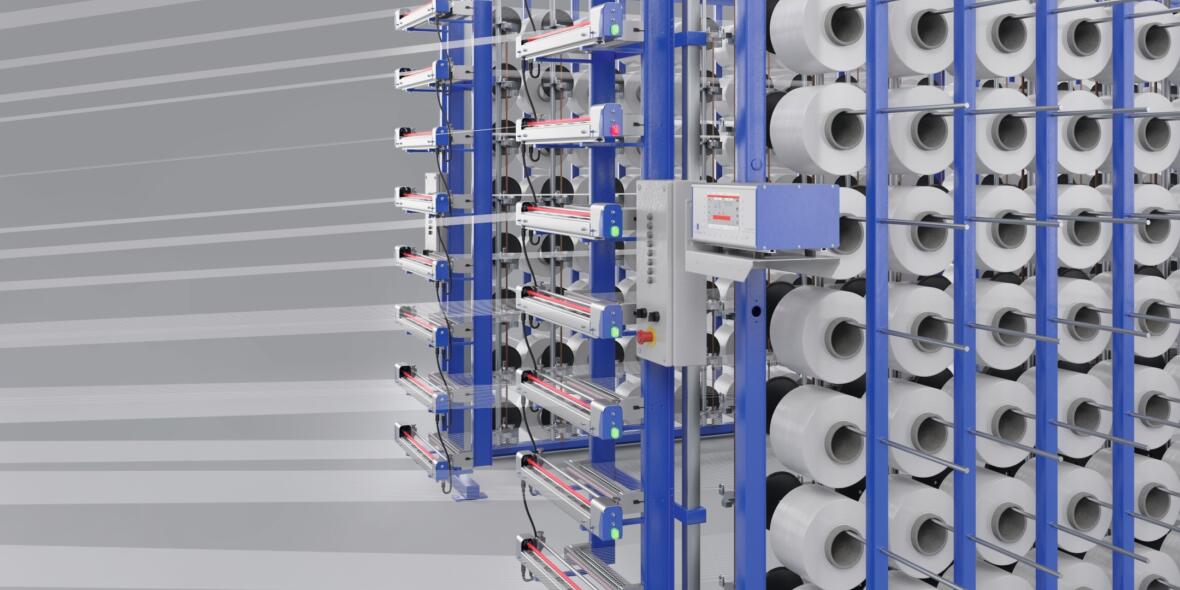

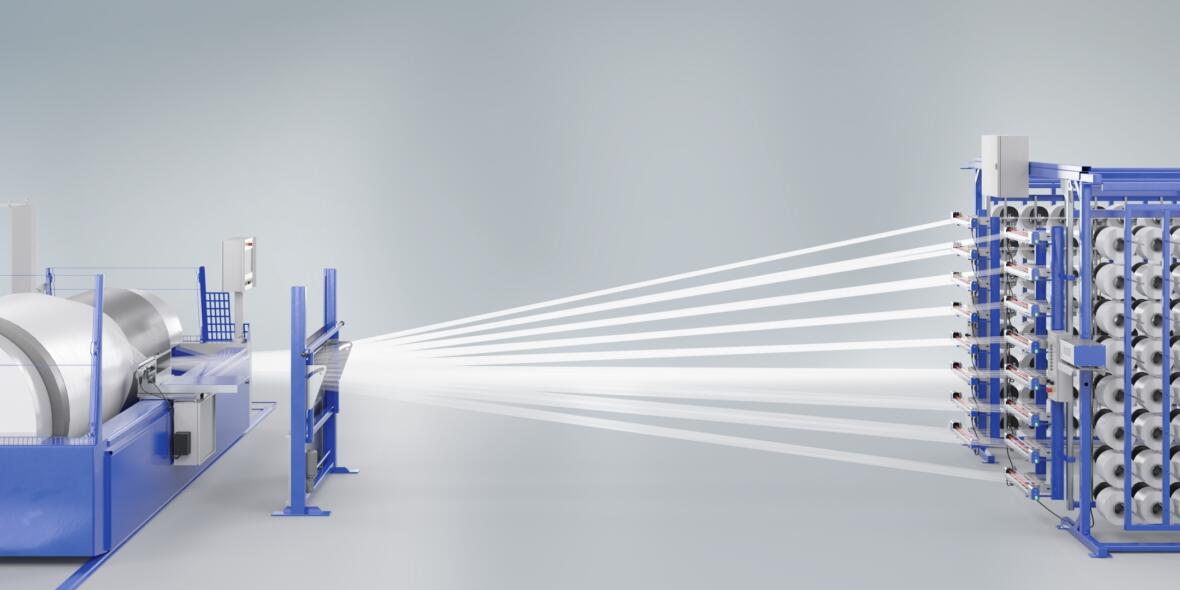

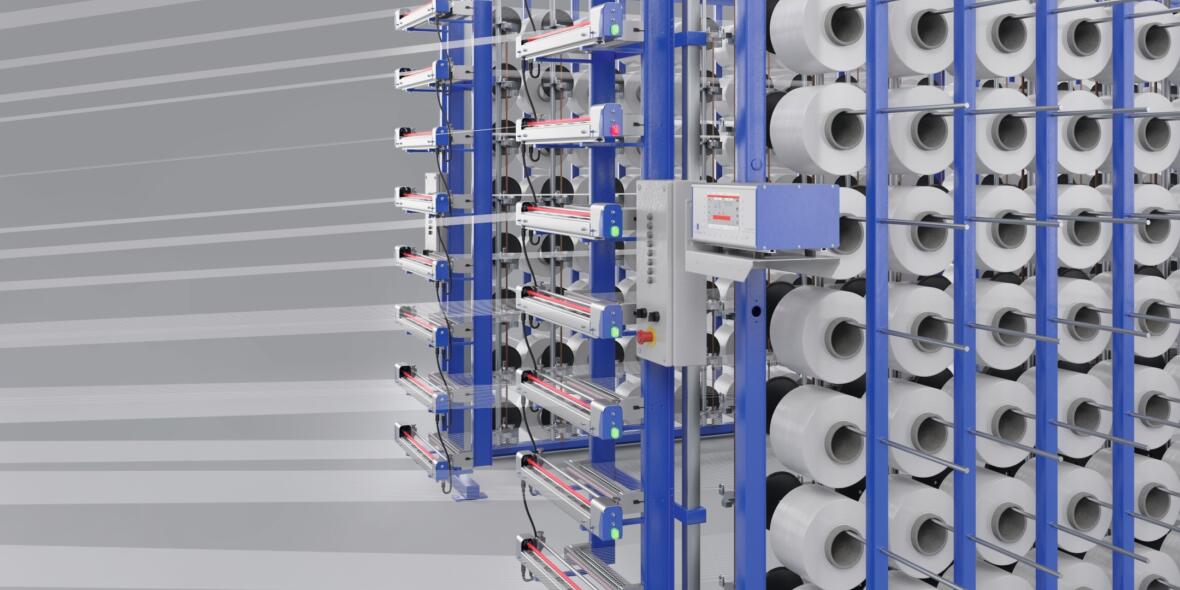

The COGASTOP CREEL 2 3210 yarn monitoring system is used for the automatic detection of yarn defects affecting spun and filament yarns during the Warping and Beaming process. Slubs, double threads, knots and spinning defects can be detected. Monitoring is performed directly on the creel on all levels on the creel outfeed. To facilitate this, the inspection heads with beds for yarn guidance are attached to a special mounting frame or, where possible, on the creel itself. The number of yarn guidance beds in the system matches the number of creel levels. With electronics fully integrated into the inspection heads plus an active optical system, the system set-up is very robust and resistant to failure.

- Adjustable machine stop, based on defect size and defect frequency

- Data transfer via USB pen drive or network to connect to ERP system or MES

- Input of operating parameters into a central control unit

Features

Reliable monitoring

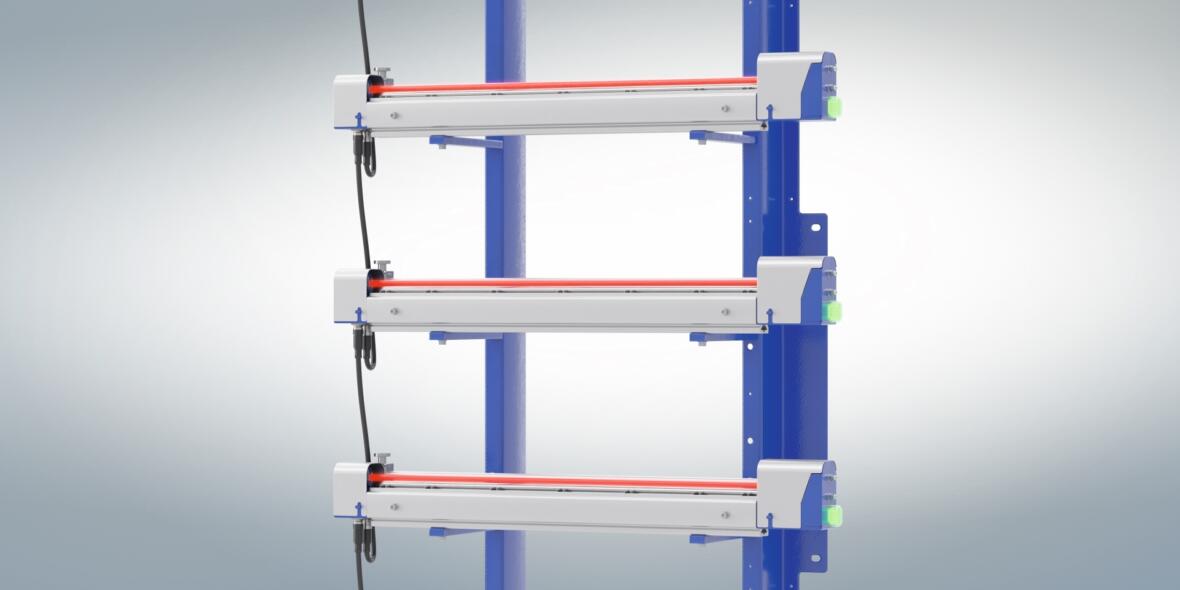

Thanks to the use of active transmitter and receiver units, the inspection heads with beds for yarn guidance are easy to adjust, and facilitate infinite and automatic sensitivity adjustment to match different yarn diameters. The multi-coloured status display integrated into the side of the inspection head keeps operators updated on the current system status even when standing some distance away near to the warping drum. This gives operators an easy way to identify yarn guidance beds with anomalous signal levels. The creel level where a slub has been detected can be identified immediately. A machine stop can be configured based on the size and frequency of defects.

Easy operation

Operating parameters for the COGASTOP CREEL 2 3210 are entered directly into a central control unit. The integrated display features an intuitive and multilingual menu system. The number of slubs detected is displayed on the control unit both as a total and as separate figures for each yarn guidance bed.

YARNWATCH

The YARNWATCH application provides operators with PC-based monitoring of their COGASTOP CREEL 2 3210 systems, with all production data collected being stored in a database for later analysis. The YARNWATCH user interface gives the operator a quick rundown of the current system status, the beams produced and the creel loads processed. Yarn-specific settings can also be stored as a ‘yarn type’.

Open and flexible bus architecture

The Ethernet-based bus system means individual yarn guidance beds can be easily connected together in series with cables, offering a simple way to expand the system to meet future needs. Since the power supply is integrated, no separate power cables are required. The system’s current, beam-based measurement data can be exported from the control unit onto an inserted USB pen drive and then used in later statistical analysis work. A network port is also provided with an open data protocol for connecting the COGASTOP CREEL 2 3210 to an ERP system or MES.

Product tour

| Description | Value |

|---|---|

| Yarn speed: | From 30 m/min up |

| Monitoring widths: | 580 mm/680 mm/780 mm |

| Visible, non-hazardous red light laser: | Class 1 |

| Operating voltage: | 100V–240V / 50Hz–60Hz |

Submit your data and you will be contacted by one of our experts