Form - TENSOSCAN 2 5374

TENSOSCAN 2 5374

Information about installation and yarn sheet

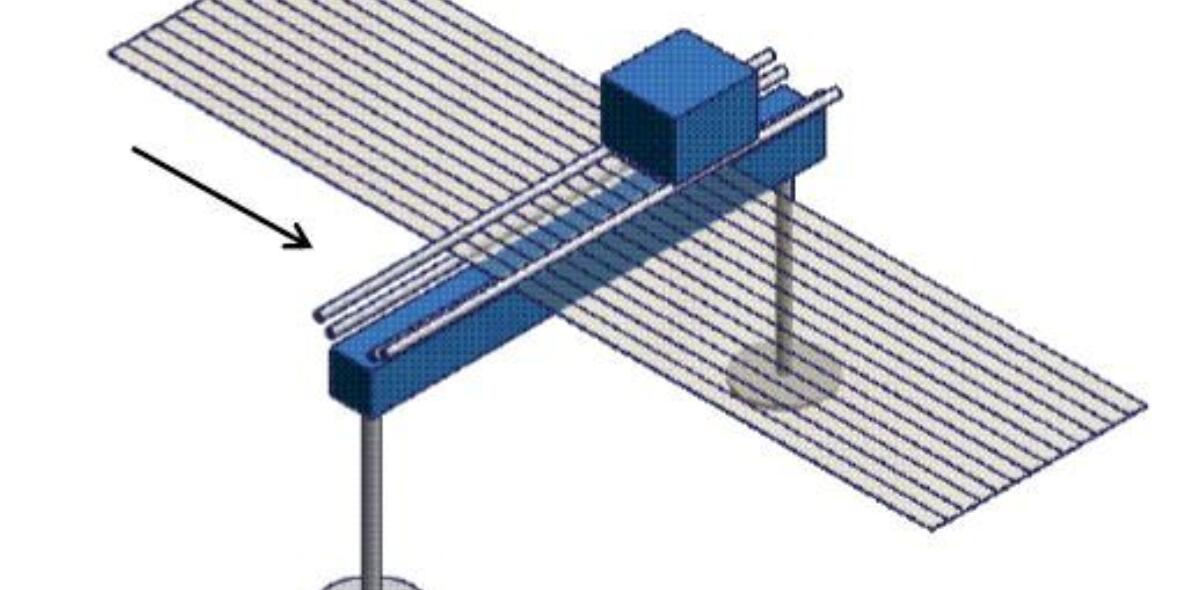

Version A

The yarn sheet is already led parallel and in one level.

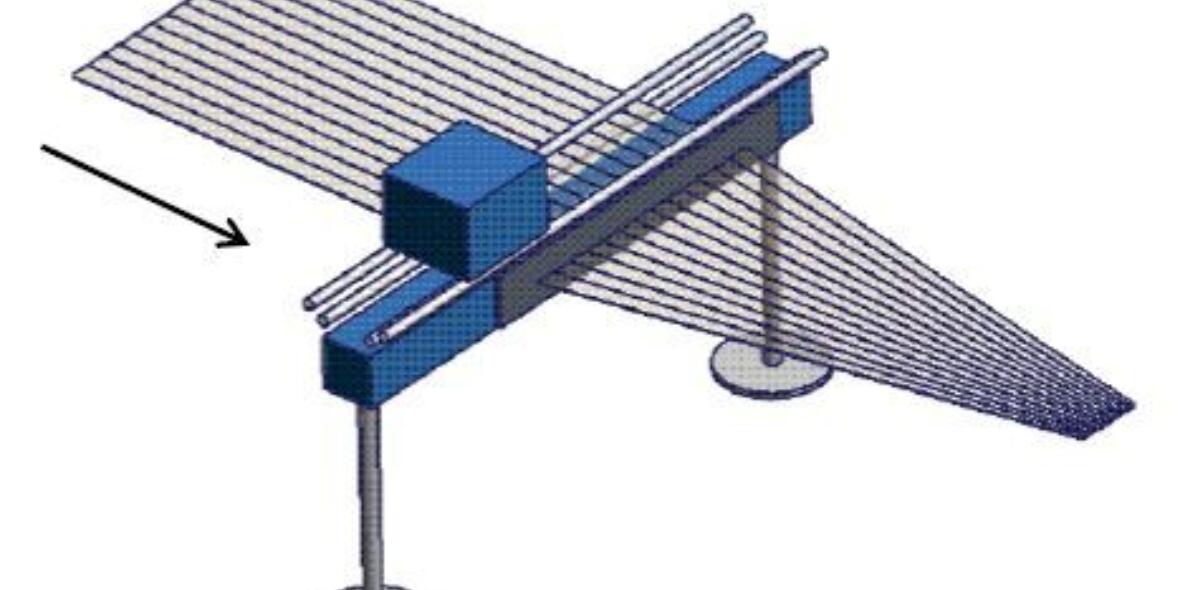

Version B

The yarn sheet runs parallel towards the TENSOSCAN 2. An additional reed at the yarn exit of the TENSOSCAN 2 ensures that the yarn sheet is running in parallel across the TENSOSCAN 2.

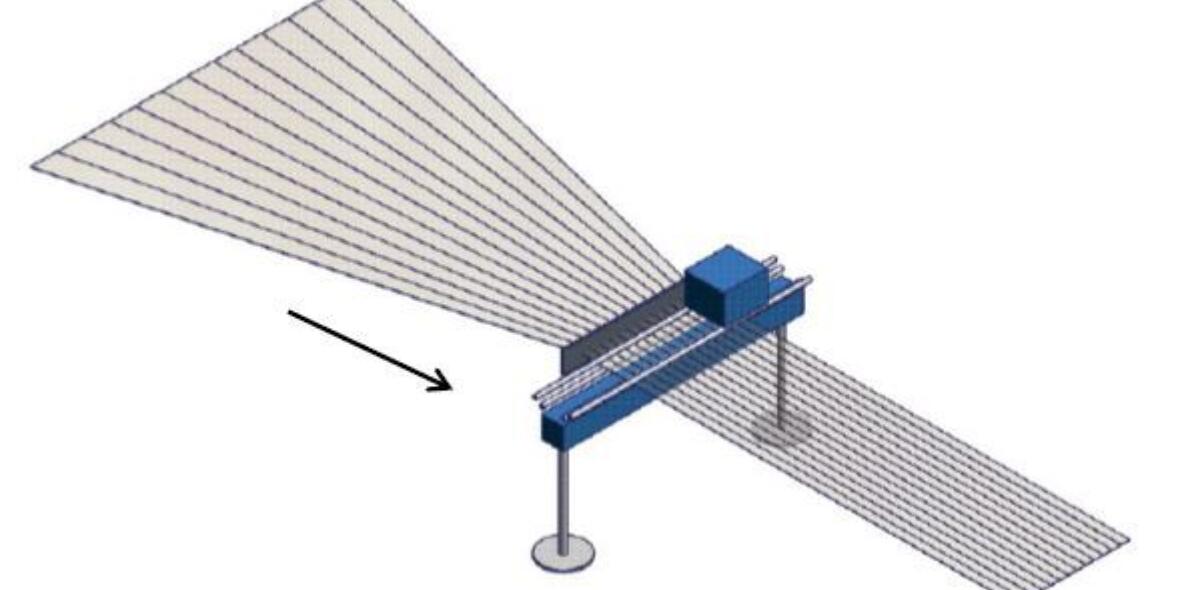

Version C

The yarn sheet is running v-shaped towards the TENSOSCAN 2. An additional reed at the entry of the TENSOSCAN 2 ensures that the yarn sheet is running in parallel across the TENSOSCAN 2.

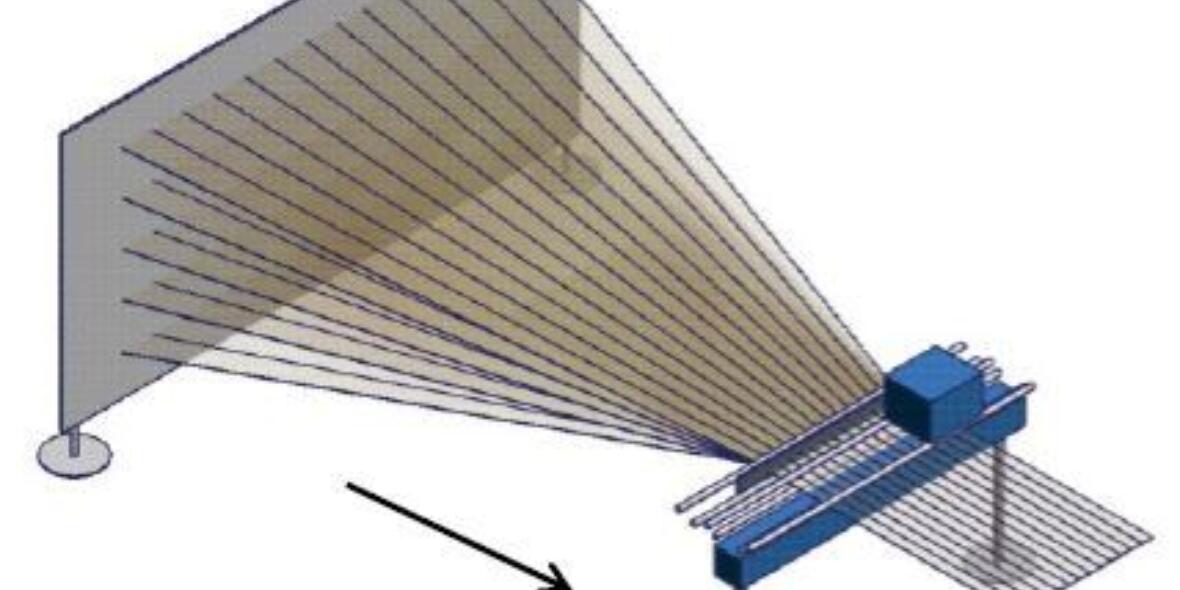

Version D

The yarn sheet runs from the creel or eyelets board in multiple levels towards the TENSOSCAN 2. Additional yarn guide rods and an additional reed at the entry of the TENSOSCAN 2 ensure that the yarn sheet runs parallel and at one level across the TENSOSCAN 2.